In scrap metal recycling, metal shredders are used to reduce the size of metal scrap. Using a metal shredder is a highly efficient way of processing scrap to obtain a high value. At Advance Hydrau Tech, we build complete shredding systems for a wide variety of metal scrap such as LMS (light melting scrap), car body scrap, medium-sized commercial scrap (bicycles, rickshaw body, white goods), etc. Based on the space available with the customer, we can build either a single-line, a C-shaped or an L-shaped shredding system.Shredding systems built by us have a processing capacity of 10 tons/hour.

However, to fulfil the rising demands and needs of quicker and advanced scrap processing, we have partnered with Newell Recycling Equipment, USA, to offer shredders which have a processing capacity of up to 30 tons/hour. Our aim is to provide our customers with a cost-effective and technologically advanced solution.Shredders built by us are easy to operate. They can be operated automatically through a PLC or electronic control panel. They possess a long service life with low maintenance needs, have an oil lubrication system to reduce the wear and tear, and have reversing systems for overload and emergency features to ensure safety.

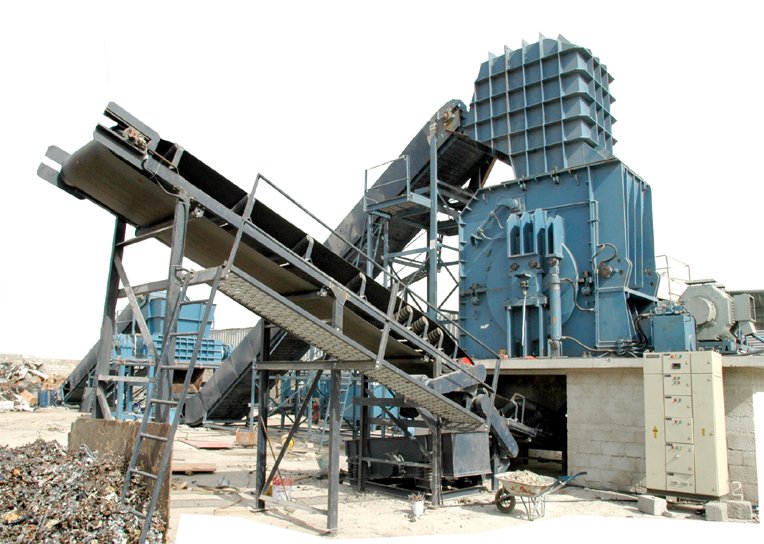

Our complete Shredding system typically includes:

- Infeed Conveyor accepts scrap-metal and puts it into the pre-shredder.

- Pre Shredder includes rotary shear (twin shaft shear) which cuts and crushes voluminous light metal scrap like automobile body, drum, white goods body, etc., into smaller pieces. It has two rotors driven by motors and gearboxes and can bear abnormal load conditions and pre-shred without causing significant noise or polluting the air.

- Infeed Conveyor to main Shredder transports pre-shredded scrap to the main shredder. Pre-shredding is not required for the small scrap and it can be directly fed through this conveyor.

- Main Shredder then shreds the scrap and turns it into small and dense scrap. The main shredder is a robust, hammer-type shredder with heavy-duty bearings and bearing blocks.

- Out Feed Conveyor transports the shredded scrap to the metal separation conveyor.

- Non-Ferrous Separation Conveyor makes use of magnetic separation to separate the non-ferrous metals from the product stream.

- Vibratory screen removes dust and other smaller unwanted material (like plastic, wood, etc) from the processed scrap.

- A well-designed Electrical Control Panel having MCBs, safety devices, overload features and relays, is present. In case of an emergency, you can stop the entire system using the emergency stops which is provided at two places.

- There is an optional availability of oil lubrication system and cooling system.

Types of Shredders

- Single Shaft Shredder

- Twin Shaft Shredder/ Rotary Shaft Shredder/ Pre Shredder

- Hammer Mill Shredder