Scrap Baling Machine also known as scrap baling press or Scrap bundling machine is used to compress waste/scrap into bundles. The scrap may be metal, paper or plastic. Increasing line of wastage is a global phenomenon. Wastage vary in their material form. Industrial trash is pollutes all forms of nature – air, water and earth. Reprocess wastage will be a great aid for environmental benefits. It also adds to cost cuts in expenses as recycled products can be used again by industry. Some materials don’t have property to decompose while others are recyclable. Role of scrap baling machines starts from here. Metal recycling makes recycled product new and ready for use. Recycling equipment enables one to conserve the limited resources at hand and create new products out of scrap material available with you. Some of the most used recycling equipments include baling machine, shredders, conveyors, compactors and scrap metal baler.

Ferrous materials are stainless steel cast, wrought iron, carbon steel and mild steel. Contrarily non- ferrous materials are aluminum, copper, silver, brass and lead. Some recyclable products include doors and windows, old car bodies, auto parts, cast iron pipes, machinery, appliances, rails, soda and tin cans, tram tracks and water tanks and heaters. Bailing machines salvage them through their features like – ensuring longer service life, resistance against compressive strength and corrosion.

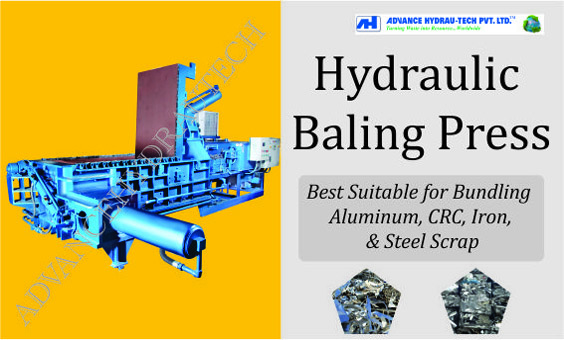

With more diversification in size of scrap size of machines vary accordingly. A metal scrap baler can be used to form solid blocks of waste metals like steel for easy handling and transportation. Depending on the baling machine owned, the recyclable blocks vary in size, shape and weight. In recycling industries out of the many variants available in market, vertical balers are typically used. Ferrous or non-ferrous any kind of materials can be compacted through these machines. These machines consume less power and require less maintenance.

Next in the series to be included is iron scrap baler press. They can be used on both kind of metal and process of this baler includes –

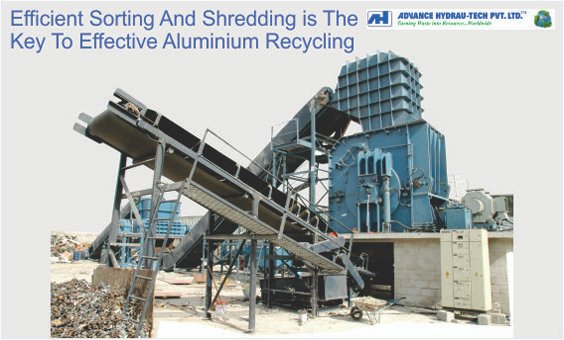

Sorting – Since materials are mixed up, so this process includes sorting it in different category.

Baling – In this process scrap baling press is used. Pressure is used to compose the scrap material.

Shearing – To break it into considerable unit is to be done in shearing process.

Separation – When metals are blocked in particular sizes, they are separated.

Melting – Finally the scraps are melted and castled into slabs.

Slaps are ready to be used again by industry. The process of iron scrap baler does not alter the property of material and reduce the expenditure on global energy and pollution.

The great array of functions of ferrous and non-ferrous metals has compelled humankind to implement techniques to use it and reuse it and contribute towards Eco friendly world. Equipments like scrap baler machine are not only a boon to industrial waste but also play a pivot role in pollution free earth. With such scrap baler machines not only the burden on natural resources is diminished but also avoids the risk involved in land, air and water. It lessens the burden of industrialists as its curb their expenses and gives them a chance to contribute towards green earth.