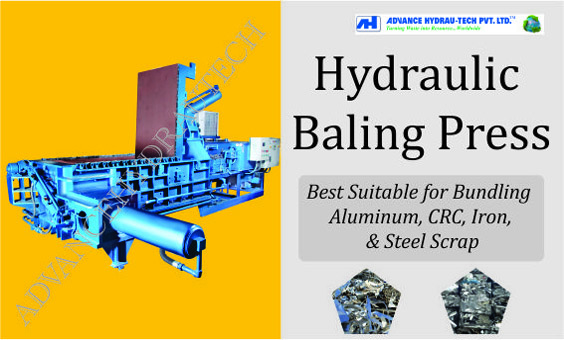

Hydraulic baling press is one of the most important machine in scrap processing industry. The scrap metal recycling industry is shaping the global economy which is inching towards becoming more circular. Businesses are learning to take advantage of new technology to recycle outdated equipment. However, most businesses still lack the knowledge and awareness about recycling their metal waste in a cost effective manner.

A Hydraulic Baling Press has several applications in steel mills, metal processing industries, and even smelting industries. Balers help pack large quantities of recyclable material into condensed packages for easier storage and cargo.In case of metal recycling industries, a baler can be used to extrude various metal scrap into bales, thereby reducing the storage space as well as transportation cost required for disposing off waste metal. They also allow for increased commodity values by maximizing the value of each bale. Typically, balers are used to crush recyclable materials such as cardboard, paper, plastics and metals.

Hydraulic baling press can effectively turn waste into a resource when selected prudently by keeping all important requirements from the machine in mind.

Business owners routinely find themselves in a predicament when they have to zero down the right type of recycling and waste processing equipment for their operations. The equipment often requires a significant amount of investment and the right equipment can bring innumerable benefits to the business. Investing in the right waste management system can help a company cut costs and increase its efficiency.

Following are certain factors that every business owner should consider before choosing a hydraulic baling press for his or her business operations:

1. The Amount of Raw Material to be Baled

The most important aspect that should guide the business owner’s decision to purchase a certain type of baling machine is the quantity of material that needs to be processed. Each business is different and produces different volumes of material that requires processing. It is important to have an estimate of the requirement of the business before making equipment purchasing decision.A hydraulic baling presscomes in multiple sizes and are differently priced based on their size and capacity. Before making the investment on the machine, a company should be clear about the amount of material it intends to process and recycle on a regular basis. It is not wise to overpay for capacity that the business doesn’t produce. At the same time, it is not the best option to settle for an undersized unit as it can bring down the efficiency and cause monetary losses.

2. Lifespan of the Equipment

A hydraulic baling press can be worked continuously for long hours to maximize production, which is why their durability is extremely important. Before making a purchase, the business owner must analyse the requirements and match it with the lifespan of the machine. Factors such as longevity of equipment and part replacement guarantee as well as service schedule for machine upkeep are important considerations when purchasing. Being informed of these concerns can help businesses factor in the equipment downtime, and plan their work and budget accordingly.

3. Raw Material to be Processed

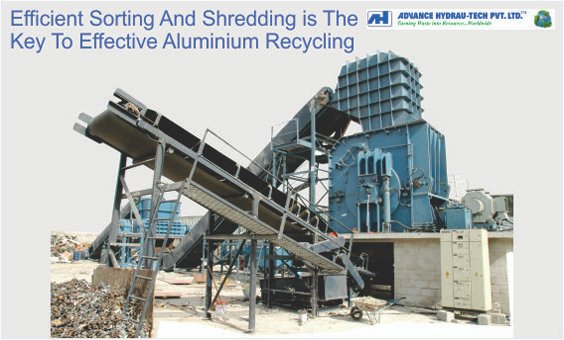

The type of material to be condensed is one of the main deciding factors for the purchase decision of the type of hydraulic baling press. The nature of business and the waste material that is being disposed off or recycled influences the choice of equipment that is right for the company. Choosing the right recycling equipment can help the company recycle in an economically viable and environmentally suitable manner.

4. Safe Operation of Equipment by Staff

Balers are a type of heavy machinery with a lot of moving parts and crushing rams that need to be handled very carefully. Safety features of the equipment and provision of training of staff are two major considerations that a company looking to buy balers should be looking at before making the purchase. Working conditions of the staff operating this machinery should be a priority for the company. At the same time, proper equipment handling is a must to help prevent accidents on the job, so companies need to invest in training to help protect workers.

Benefits of Using a Hydraulic Baling Press:

• Lowers the cost of disposal of waste.

• Provides an easier recycling process that can help generate a hassle-free and clean work environment. Assists in generating additional income through processed waste.

• Makes storage or transportation of materials easier.

• A company can make the right purchasing decision by first analysing and understanding their equipment needs, and by taking into account the feedback and referrals of other business owners. These steps will help them find the right hydraulic baling press for the job.