Baling machines are important recycling equipment for scrap management. They help to compress and package waste materials into nice, neat bales that can be easily stored or transported. The advent of the baling machine has revolutionized the way scrap is managed. In this article, we will take at how different types of baling machines help in scrap management and some of the benefits this brings for both individuals and businesses.

What are baling machines?

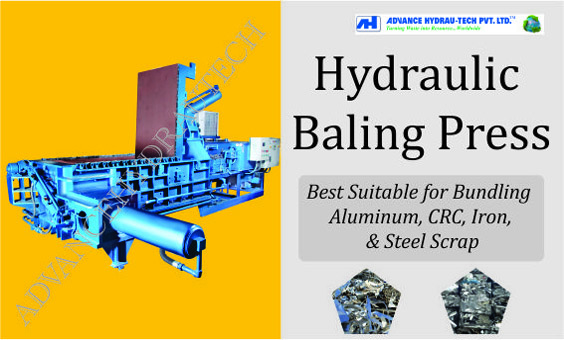

Scrap metal and waste materials are compressed into dense blocks using balers, also known as baling machines. Our hydraulic baling press can compact ferrous and nonferrous metals to increase scrap density. In addition to reducing transportation and storage costs, it is easy to handle and load into furnaces.

Our company is one of the leading manufacturers of hydraulic scrap baling machines in India. Metal scraps of any size can be processed with our hydraulic baling press machines, regardless of their size. High-quality materials are used in the construction of our balers to ensure they last for many years. We reduce your operating costs and save you time by building semi-automatic and automatic scrap baling presses.

There are two main types of baling machines: manual and automatic. Manual balers require operator input in order to function, while automatic balers operate on their own once they are set up properly. Overall, both types of baling machines play an important role in scrap management. They help to compact waste materials into manageable packages that can be stored or transported easily. This helps to keep the environment clean and organized, making it easier for everyone involved.

How baling machines help in scrap management

Baling machines play an important role in scrap management by helping to reduce waste and minimize environmental impact. Some of the ways in which they help include:

- Compression: Bale compression helps to reduce volume, making transportation and disposal much easier. It also helps to prevent moisture absorption, which can cause spoilage or corrosion.

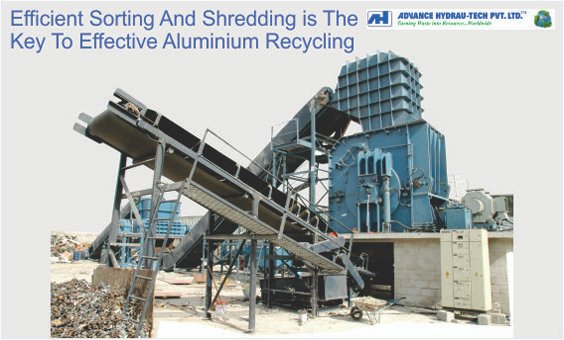

- Separation: The compaction process helps to separate different types of scrap material, making it easier to recycle them individually. This also reduces pollution caused by improper disposal.

- Collection: With proper baling machine installation, you can have a central collection point for all your scrap material. This makes it easier to monitor and manage than if it was scattered around your property.

There are different needs for managing metal scrap among customers, so we build balers to meet those needs. Every aspect is taken into consideration, regardless of the scrap type you have, what quantity you need to bale, or what level of productivity you require. The companies we serve include melting units, furnaces, scrap yards, rolling mills, as well as larger manufacturing plants that generate scrap metal. Our machines are capable of handling copper, iron, steel, MS, zinc, aluminum, and other ferrous and nonferrous scrap material.

In addition to heavy-duty Jumbo plus balers, we offer quad action balers, triple-action balers, double-action balers, continuous baler, automatic balers, single-action balers, mobile balers, vertical balers and car balers.

Conclusion

This article looks at how baling machines work and their benefits to scrap management. Baling machines have proved to be of great help for scrap management. These machines are used to compress scrap into compact bales that can be easily transported and manage scrap in efficient manner. In addition, it enables the collection of large amounts at a go and thus reduces the labour cost.